Compressed air is one of the largest energy users in industry and is used for a variety of purposes:

- Working energy air – for pneumatic tools and drills.

- Active air – to operate conveyor systems.

- Process air – for drying processes, injection blow moulding, packaging, or aeration.

In some countries it accounts for up to 30% industrial electricity use.

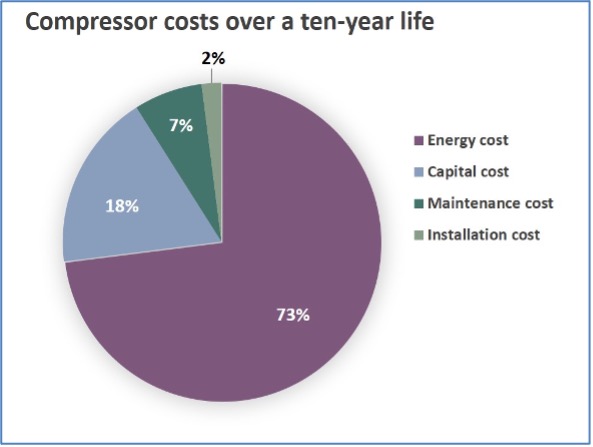

Typical air compressor costs over a ten-year service life. Up to 73% of the cost is electricity use. Data source: Carbon Trust 2012.

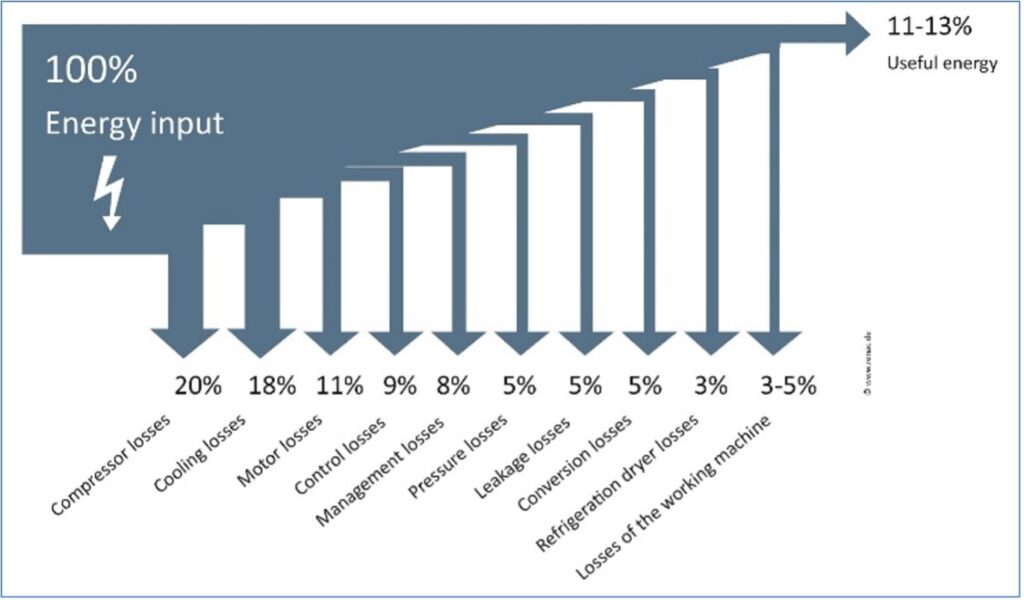

Losses occur in all subsystems of compressed air system, as can be seen in this energy flow diagram of a typical compressed air system.

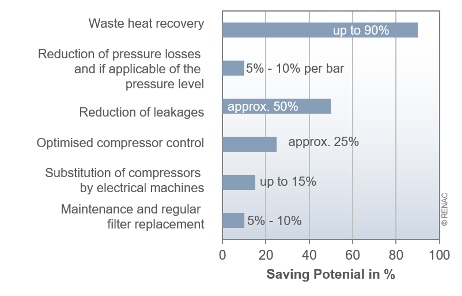

Measures that can potentially be taken to save energy include:

- Substituting to electrically driven systems – electrical drives have higher initial costs but lower operating costs.

- Regular and correct maintenance to reduce leaks and pressure losses.

- Correct compressor sizing. If higher pressure is only required for certain applications, secondary compressors for recompression should be used rather than basing the entire system on the highest pressure requirement.

- Recovering waste heat, using the heat recovered for other purposes such as pre-heating process water.

- Repairing compressed air leaks.

Potential energy-saving measures in compressed-air equipment.

In order to assess the energy saving potential, all subsystems need to be considered: application, distribution, processing and production.