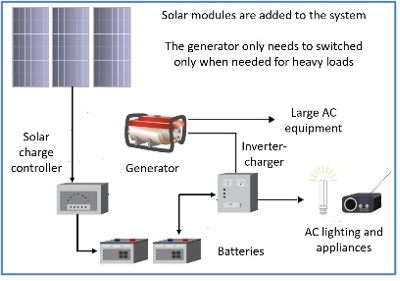

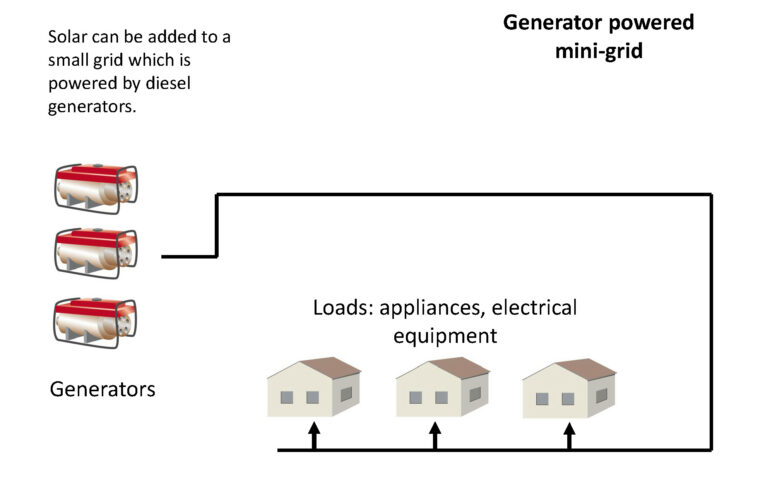

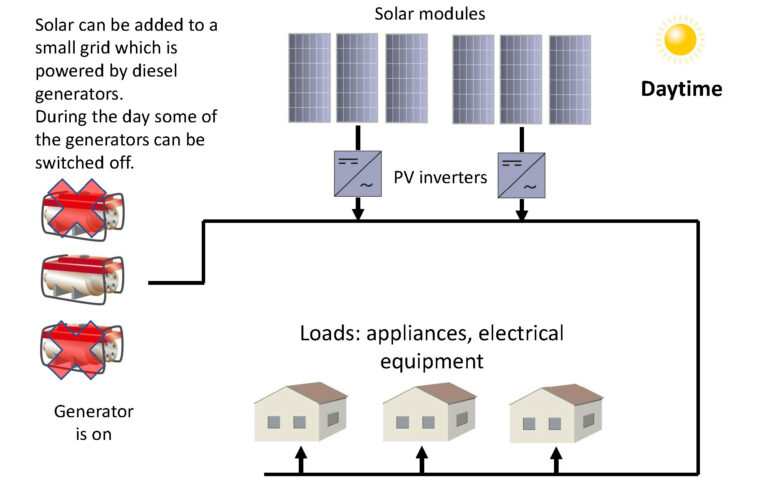

In an off-grid mini-grid powered by diesel generators and without batteries, PV modules can be used to feed electricity into the mini-grid. The amount of electricity (and thus fuel consumption) that the diesel generators need to provide is reduced.

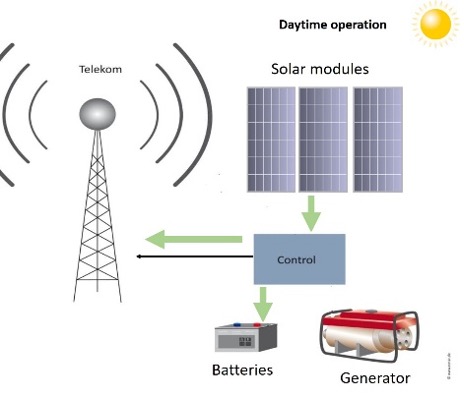

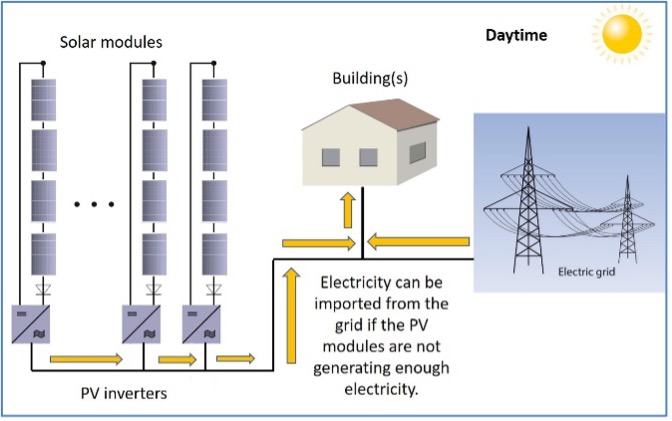

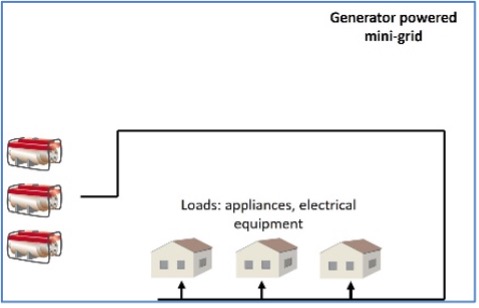

An example of how a PV-diesel mini-grid without batteries functions.

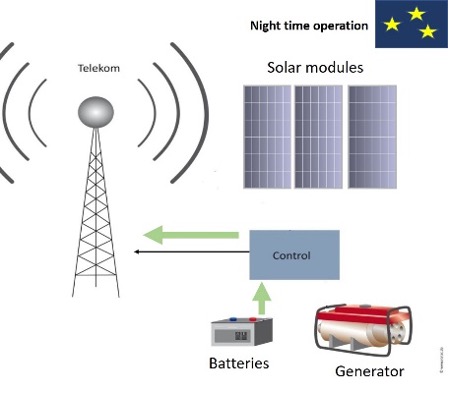

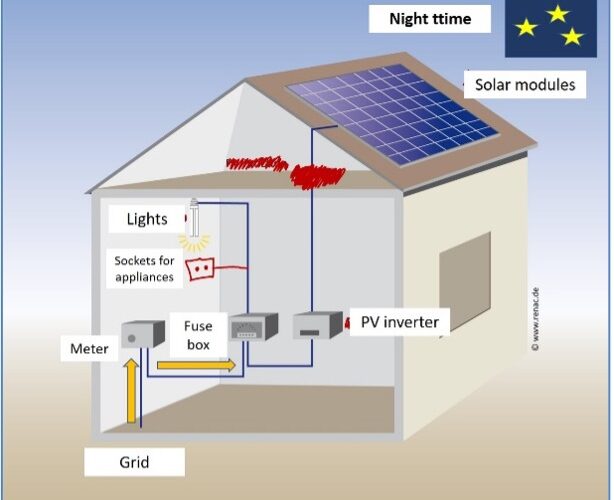

At night, when there is no sun, all three diesel generators provide power.

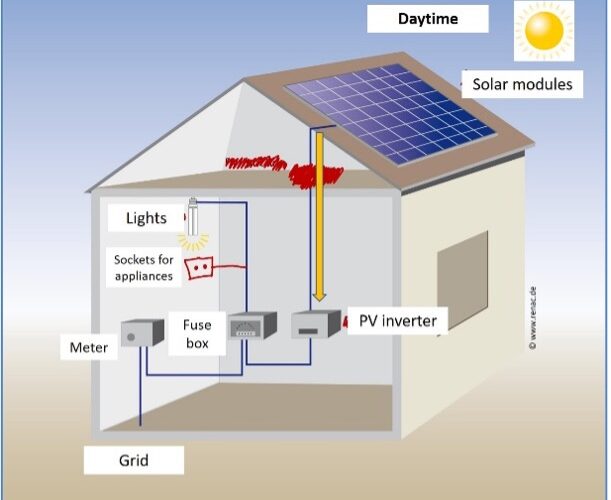

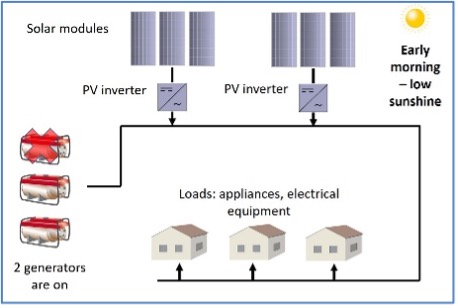

Early in the morning, when solar irradiation is low, some power is generated by the PV modules, and one generator is switched off.

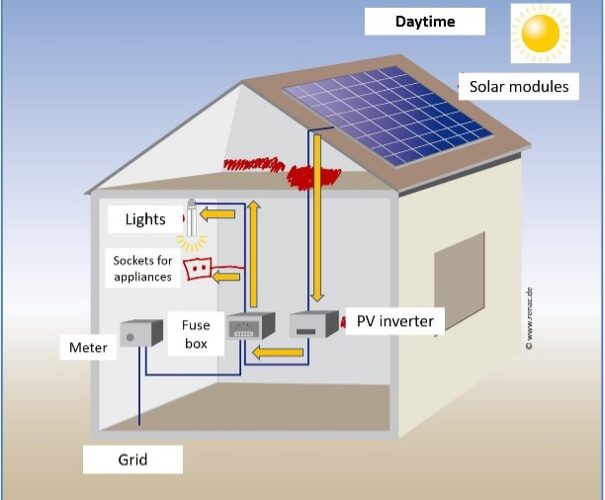

Towards the middle of the day, when solar irradiation is high, another generator is switched off, because more power in being generated by the PV modules. One generator always needs to be on to maintain the grid voltage.

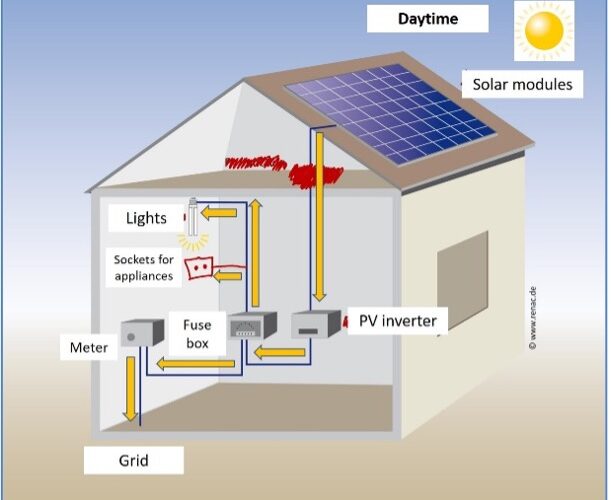

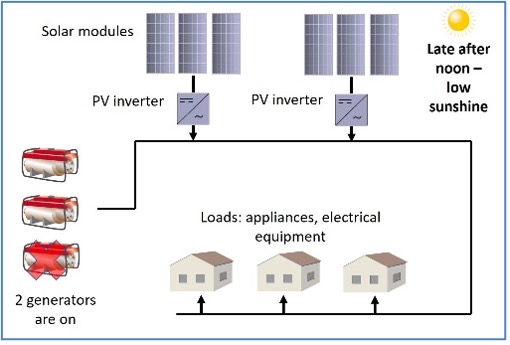

In the late afternoon, as the solar irradiation decreases, some power is generated by the PV modules, and another generator is switched back on.

How exactly a system will function will depend on the system load profile and other factors.

Savings of up to 60% in fuel costs can be made, depending on factors such as solar irradiation levels, the load profile (when and how much electricity is used) and the generators. This type of system is very suitable for industrial and agro-industrial applications where power requirements are high during the day when solar power is available. A professional load profile survey is required to size the solar component of the system optimally. System suppliers need to be consulted regarding generator system compatibility and other technical details.

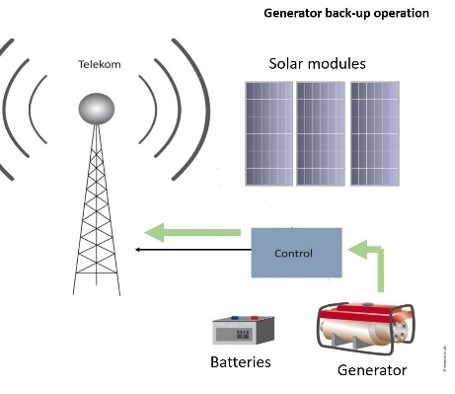

Some of these systems also incorporate small battery banks to cover lighter loads in off-peak periods.